Related product

-

- method

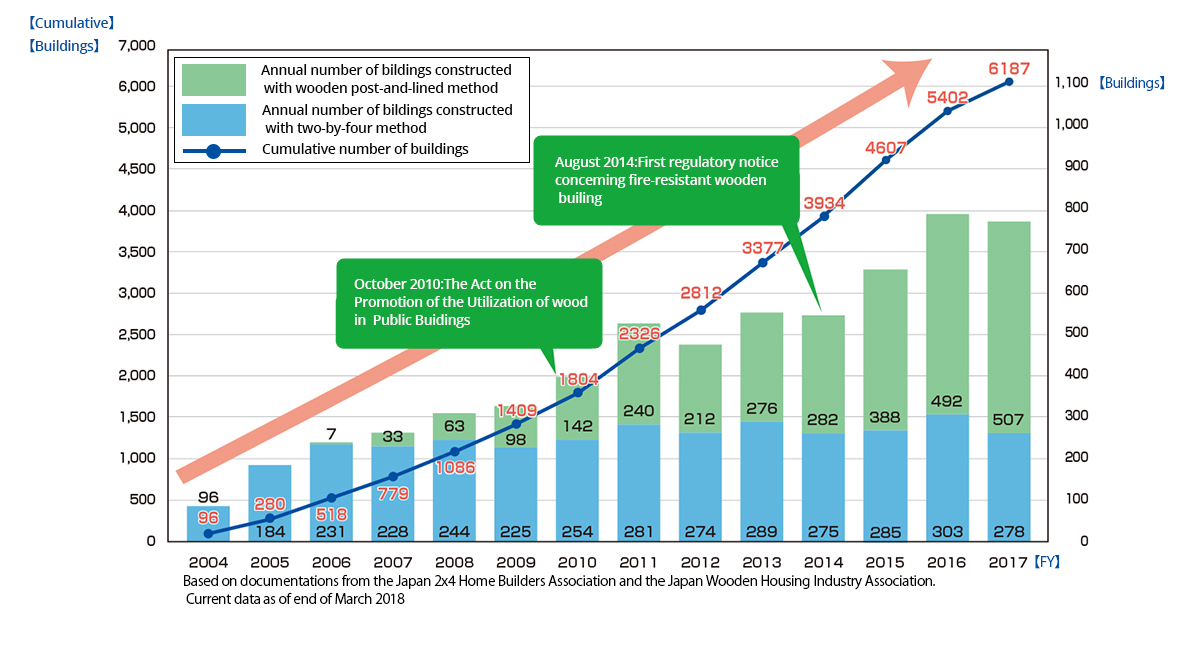

| 2000 | "Revision of the Building Standard Law Even wooden buildings can now be made fire-resistant." It becomes possible for fire-resistant buildings to be constructed with wooden materials |

| 2004 | Japan 2x4 Home Builders Association acquires fire resistant structure certification. |

| 2006 | Japan 2x4 Wooden Housing Industry Association acquires certification for fire-resistant construction |

| 2010 | The “Act on the Promotion of the Utilization of Wood in Public Buildings” is enacted As a rule, all low-rise public buildings are to be made using wood |

| 2012 | Yoshino Gypsum acquires certification for “Tiger Moen EX-B1” together with Nichiha |

| 2013 | Yoshino Gypsum acquires certification for “Exterior wall for fire resistant system with Duracrete finish” |

| 2014 | First regulatory notice concerning fire-resistant wooden construction (starting with MLIT Public Notice No. 861) Exterior wall and partition wall for fire-resistant wooden structure using gypsum board are now stipulated in the regulatory notice |

| 2015 | Yoshino Gypsum acquires certification for “Tiger Moen EX-B2” together with Nichiha |

| 2018 | Public announcement regarding fire resistant wooden structure (Announcement No. 472 by the Ministry of Land, Infrastructure, Transport and Tourism) Announcement of the specifications of fire resistant columns, floors, beams, roofs, and stairs made using gypsum board |

The state of issuance of approval for the usage of Minister Certified Specifications for fire-resistant wooden building (Cumulative number from 2 Associations)

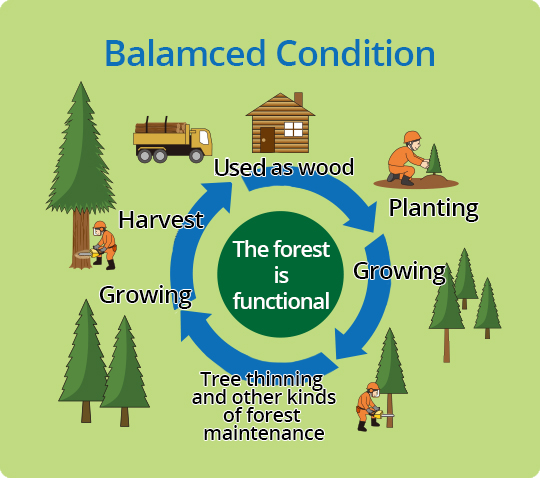

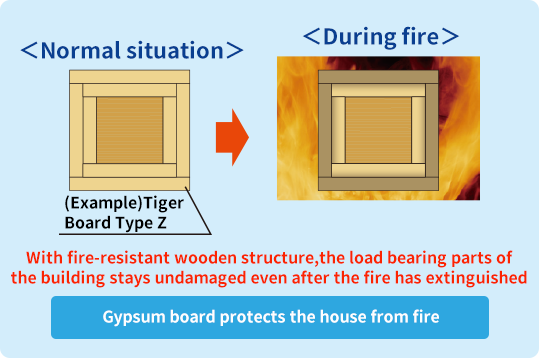

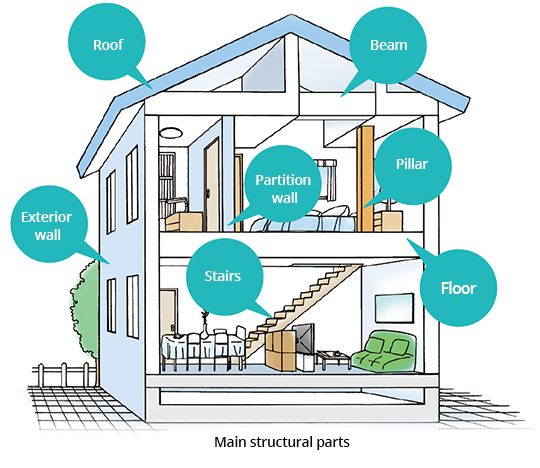

Fire-resistant buildings are required to have the ability to keep standing without breaking down even after the fire has extinguished, which is achieved by making the main structure a fire-resistant structure.

As for fire-resistant wooden buildings, the wooden structure can usually be protected from fire by cladding the wooden structure with fire-resistant gypsum boards.*

By making the building as a fire-resistant wooden structure, it is possible for the construction to be done without using heavy equipment such as a large crane because its materials are lighter than other construction methods such as reinforced concrete structure or steel structure.

It can be flexibly adapted to flag lots and cramped small lands that can be obtained relatively inexpensively.

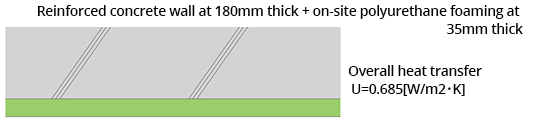

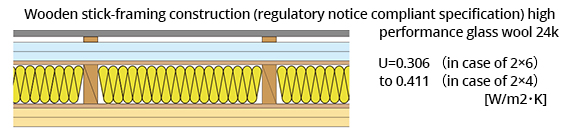

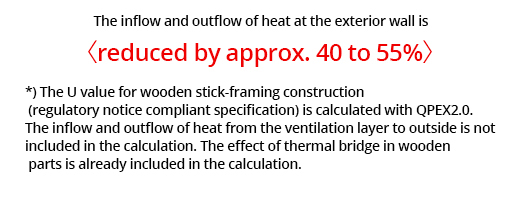

〈Comparison of overall heat transfer coefficient (heat transferablility)〉

Fire-resistant wooden structures are excellent in thermal insulation performance.

Because the indoor temperature change is small, it is possible to save the running costs for air conditioning.

With wooden structures, it is possible to write off more annual depreciation than reinforced concrete structures and steel structures.

Deprclation period comparison example between types of construction

In addition, there are tax advantages as well.

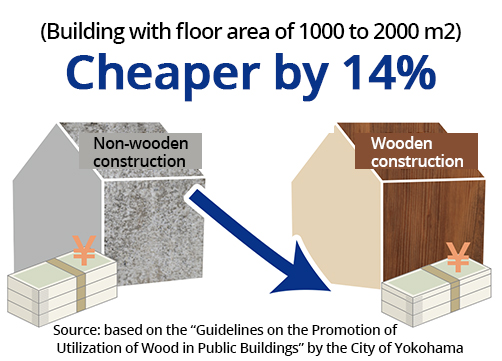

〈Comparison of construction cost (example)〉

Useful points for saving costs

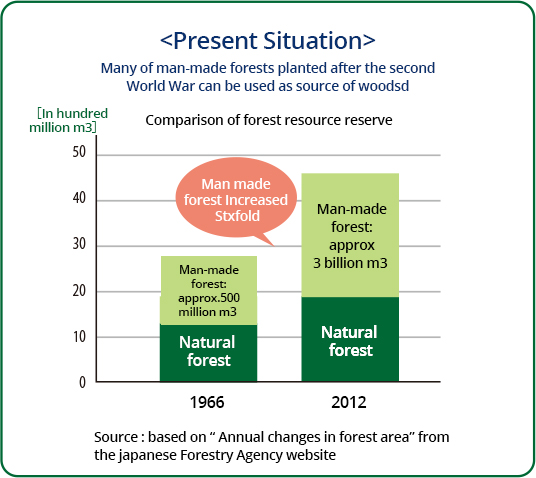

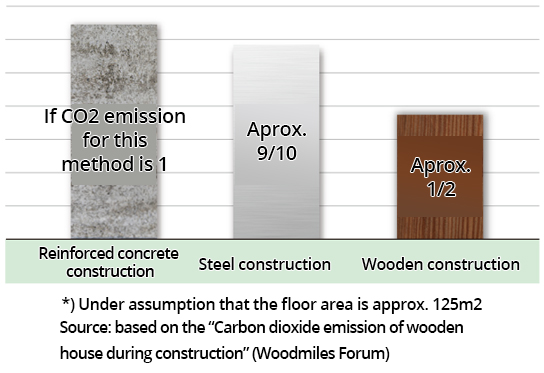

Using wood may lead to the reduction of CO2 footprint, etc., which makes it also effective for companies to improve their CSR.

In addition, by using locally produced materials, it can be expected to bring the revitalization of industrial activity.

CO2 emission during construction for each construction method when constructing one house (kg-CO2)

When questioned about which construction method to use if building or buying a house in the future, 8 out of 10 people in Japan answered that they would like to choose a house constructed of wood. The charm of the warmth of wood and its relaxing effect is widely known

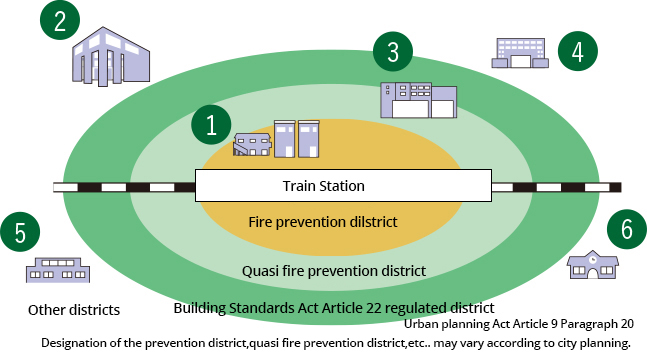

Privete housing in fire prevention district(A building with a total area of over 100 square meters ,or a three- story building.Building Standard Act,Article 27)

Buildings with a total floor space of more than 3,000 square meters (Building Standard Act, Article 21)

Buildings with a floor area of more than 1,500 square meters in quasi-fire prevention district (Building Standard Act,Article 62)

Three-story or higher special buildings such as schools, daycare center,care houses etc.Building Standard Act,Article27)

Nursing homes(Act on Social Welfare for the Elderly, Article 14),senior citizens health facilities(Long -Term Care Insurance Act,Article 97)

Kindergarten (School Education Act,Article 3)

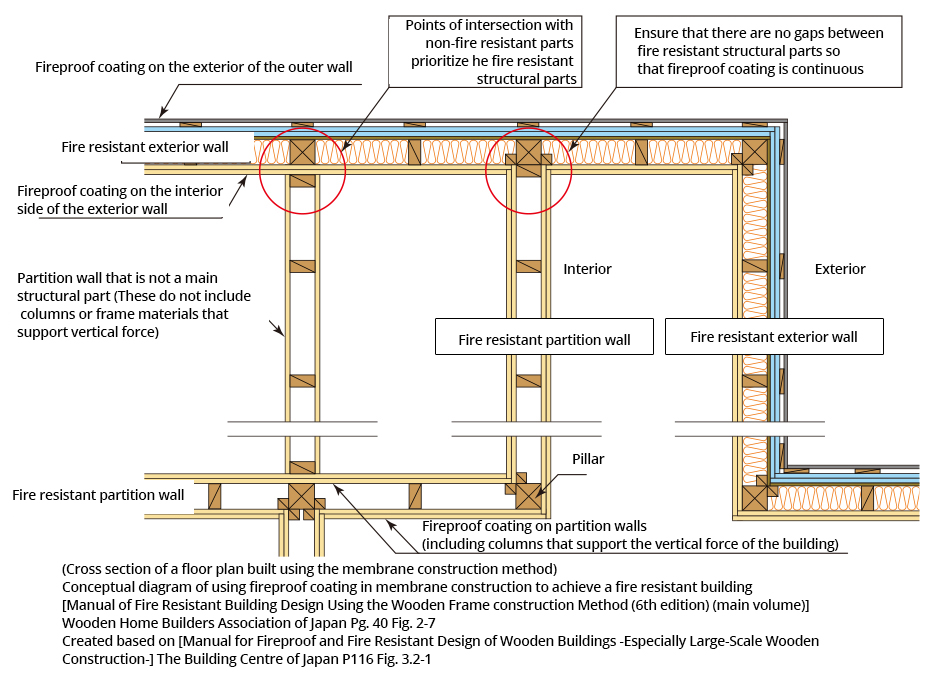

When using the membrane construction method, the specifications and fit of each part are designed based on the following concepts

[Excerpt of Technical Explanation]

2.Things to keep in mind when checking a structure

(Omitted)

Checking the conformity of fireproof coating

This annoucement only applies to reinforced gypsum boards with gypsum, glass fiber and vermiculite contents above a certain level, excluding the base paper used for the board. So far , only the following materials have been certified by the Minister of Land, Infrastructure, Transport and Tourism as non-combustible.

For materials qualifying under item 2 above and other products, please confirm conformity to the specifications based on the composition table etc.

(2)Fastening of fireproof coating

(Omitted)

From August 22, 2014, Ministry of Land, Infrastructure, Transport and Tourism Housing Bureau construction guidance No. 1785, "Technical advice regarding the enforcement of public announcements ammending certain matters determining the construction method of fire resistant structures"

[Excerpt of Technical Explanation]

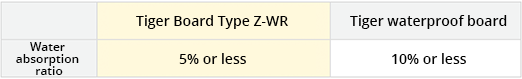

| Query from the Public | What are your thoughts regarding durability and waterproofness when using Fire Resistant Gypsum Boards as an outer wall? |

| Response from the Ministry of Land, Infrastructure, Transport and Tourism | We believe that Fire-Resistant Gypsum Board used for an outer wall must be properly maintained, and that processing to ensure durability and waterproofness, such as waterproofing and antiseptic treatment etc., must be duly considered.※2 |

Quoted from August 27, 2014, Ministry of Land, Infrastructure, Transport and Tourism, Residential Bureau, Building Guidance Section, “Responses to solicitied opinions regarding the planned partial revision of the determination regarding construction methods for fire resistant structure (Ministry of Construction Public Announcement No. 1399 of 2000) ”

"Tiger board type Z-WR" is highly waterproof.

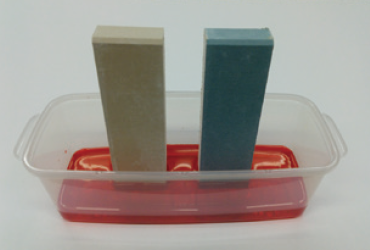

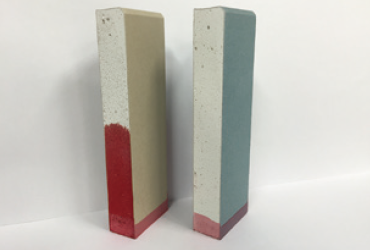

【Test Method】

The bottom 1 cm of the sample pieces of Tiger board type Z-WR and Tiger board type Z (standard fire resistant gypsum boards ) were soaked in inked water water for one hour, and the amount of water absorbed by each test piece was compared.

【During the test】

Left: Tiger board type Z

Right: Tiger board type Z-WR

【After the test】

Left: Tiger board type Z

Right: Tiger board type Z-WR

【Test results】The Tiger board type Z-WR absorbed less inked water.

"Tiger board type Z-WR" still satisfied the JIS standards (for flexural strength and moisture content) even after 5 years had passed and did not develop mold.

The durability of the outer wall of a wooden fireproof structure built with "Tiger board type Z-WR".

Covering with double-layer of Tiger board type Z-WR 21mm

Exposure outside for 1 month (during the rainy season)

Condition of the double-layered Tiger board type Z-WR 21mm after 1 month of exposure

*Although exposure has discolored the base paper, the board’s performance is not affected.

Application of exterior covering

The double-layered Tiger board type Z-WR 21mm is covered with a waterproof sheet, and ceramic siding is installed with some space between layers to allow for ventilation.

Five years pass

The state of ceramic siding after five years

The ceramic siding and waterproof sheet are peeled off to check the state of the board underneath.

【Test results】Year-over-year change of Tiger Board Type Z-WR after 5 years

| Nail pullout resistance* | Molding | Base paper peeling | Rusting of fastening screws |

|---|---|---|---|

| 100% | None | None | None |