Gypsum Board production flow

HOME ⁄ What is “gypsum”? ⁄ Gypsum Board production flow

Gypsum Board production flow

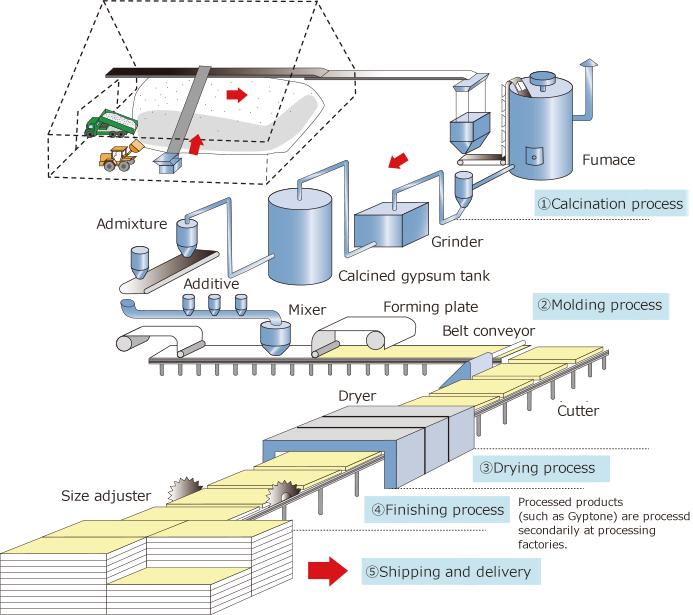

"Tiger Board" is produced in the factory automated production line. Let's see the manufacturing process.

How Tiger Boards are made [Tiger Board manufadtacturing process]

-

Calcination process

"Gypsum" is baked in a furnace and made into "calcined plaster" which will solidify when it reacts with water.

Click here to see the principle on how gypsum solidifies Chemical reaction of “gypsum” -

Molding process

Calcined “gypsum” is mixed with water to make a slurry (muddy state). Then, the slurry is poured into a line (belt) where board liners are flowing down, thus sandwiched with board liners.

-

Drying process

Boards are sent to a drying machine (dryer) to remove excess water content.

-

Finishing process

Boards are cut into products with appropriate size.

-

Shipping and delivery

Products are loaded into trucks and delivered to various locations.