User assist link

-

- Social contributions

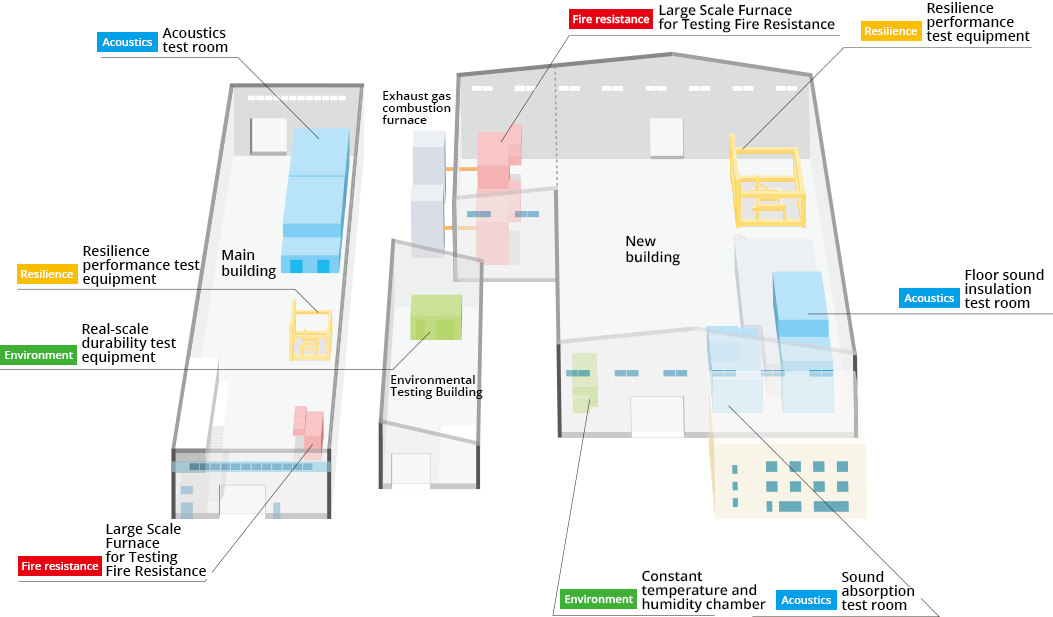

Our "Comprehensive Performance Testing Center" is equipped with facilities that can verify multiple aspects of product

functionality and safety performance.

Test results are promptly relayed to product development departments, enabling quick response to the diversifying needs

of our customer base.

We constantly pursue high-level product performance by testing to realize ever improving acoustics, fire resistance,

resilience, and environmental adaptability.

Measures the sound insulation performance of walls and realizes sound insulation performance of TLD80

※ TLD80A sound insulation performance evaluation level specified by the Architectural Institute of Japan and achieved through a acoustics test on a single wall. TLD80 means a performance five grades (25 dB) higher than the highest grade 4(TLD55)specified for boundary walls by the Product Assurance Law.

Measures "floor impact sound insulation performance", which is the resistance to transmission of the sound (vibration)

of an impact through a floor structure.

Various impact source sounds can be used, such as "tapping machine" for a standard lightweight sound, and "banging

machine" and "rubber ball" for standard heavy sounds.

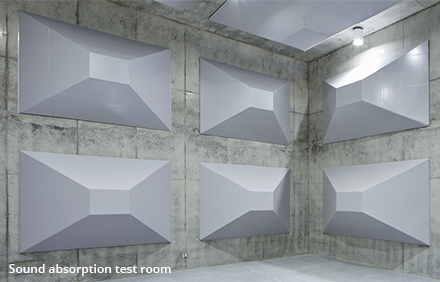

Measures "sound absorption rates" of building materials (gypsum board, glass wool, etc.).

Test subjects with back-air layers from approx. 0 to 1000 mm can be used in testing.

In addition to measuring the strength and rigidity of products under various conditions such as earthquakes, shocks, and pressurization etc., tests can be conducted to compare the material, thickness, and structure of wall materials.

In-plane shear test equipment

Tests on wooden frames and Shear walls of 2x4 houses.

In-plane deformation compliance test equipment

Deformation due to earthquake is simulated on a test subject and the damage to the finishing material is observed.

Out-plane bending stiffness test equipment

Wall deflection is measured by applying force at right angles to the surface of the test subject. Pressures up to a maximum wall height of 5m can be tested.

This equipment can test and evaluate the fireproof and fire resistance performance of partition walls and outer walls at

a level corresponding to the fire resistance test standard set under the current Building Standards Act as well as by

each public performance evaluation organization.

It can also perform load heating testing, in which the wall is heated while vertical load (up to 1,000kN) is also

applied to it.

The furnace is equipped with smoke processing equipment and can safely perform tests with high levels of smoke creation.

This test equipment that places a test subject between two rooms (chambers) that reproduce interior and exterior

temperature and humidity levels in order to test durability, etc.

The exterior chamber has an infrared lamp that artificially radiates solar heat, and a sprinkler that imitates rain to reproduce various weather conditions.

This testing equipment provides excellent temperature and humidity control, thereby allowing the reproduction of temperatures in the range of -40℃ to +80℃ and humidity conditions in the range of and 30% to 95%RH.

New building

In-plane shear test equipment (Load bearing wall)

In-plane deformation compliance test equipment (Non-load-bearing wall)

Out-plane bending stiffness test equipment (Load-bearing wall)

Main building

JIS A 1416: Type I test room specified in 2000 (reverberation room)

In-plane shear test equipment (Load bearing wall)

In-plane deformation compliance test equipment (Non-load-bearing wall)

Out-plane bending stiffness test equipment (Load-bearing wall)

Constant temperature and humidity chamber

Test equipment that meets the specification defined in the Japan Testing Center for Construction Materials standard JSTM J 7001 “Test method for thermal deformation and durability of real-scale exterior wall through the use of sunlight radiation”

Chamber for interior conditions simulation

Chamber for exterior conditions simulation

Infrared lamp

Sprinkler equipment