Fire resistance test

Verification of fire resistance performance

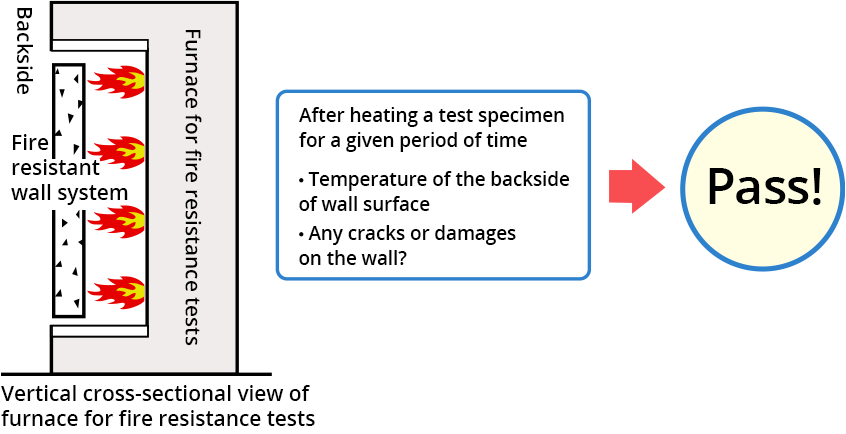

Walls for use in fire resistant structure etc. is installed in a furnace for fire resistance tests (heating furnace), the burner in the furnace is used to raise the temperature inside the furnace according to the standard heating curve, then the surface temperature of walls not facing the furnace is observed, as well as observing for wall collapse, cracks and damage.

If the fire resistance is rated for 1 hour, heating is maintained for 1 hour. However, observation will continue for 3 hours after heating to confirm the safety of the wall.

Yoshino Gypsum Co., Ltd. Total Quality Testing Center - Full-Scale Furnace for Fire Resistance Tests

Yoshino Gypsum Total Quality Testing Center is equipped with the full-scale furnace for fire resistance tests, with the test capability comparable to the fire test facilities in official testing organizations. We address the-day-to-day challenges of the research and development for creating new fire resistant walls.

Overview of Large Scale Furnaces for Testing Fire Resistance (two units)

- Subject Parts:

- Walls

- Effective Size for Fire Test:

- 3,500 (width) × 3,400 (height) mm

- Combustion Equipment:

- Natural Gas·Flat Frame Gas Burner 20

- Heating Curve:

- Standard heating curve specified in ISO・834

- Loading heat:

- Max of 1,000 kN (approx.100t)

- Supplemental apparatus:

- Smoke emission treatment equipment (maximum capacity 400 cubic m/min)